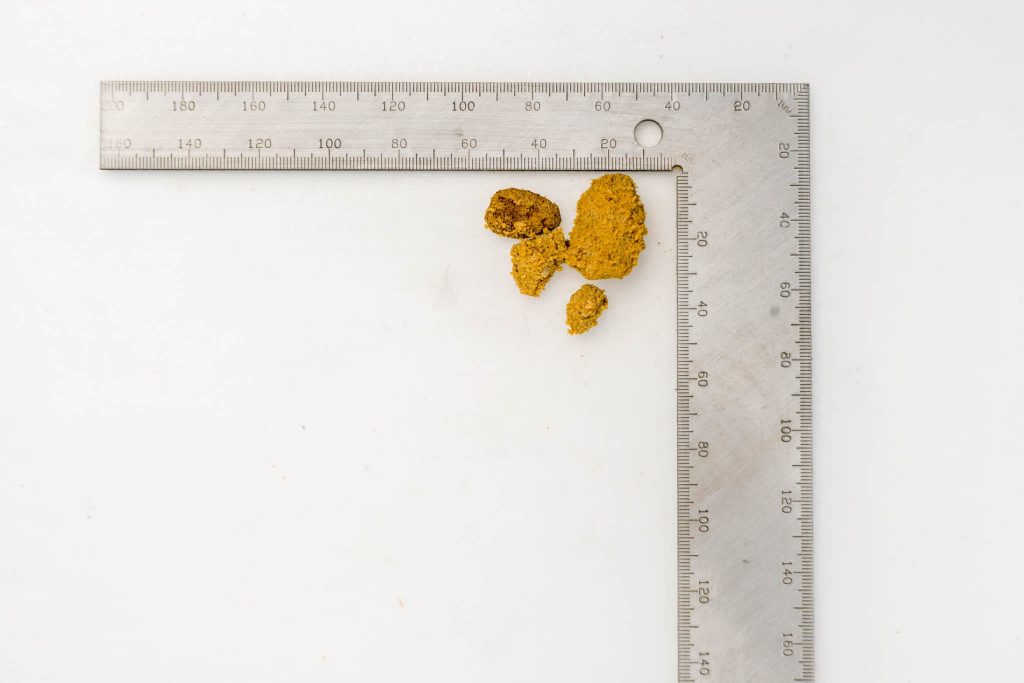

Tailings are the residual waste materials resulting from the processing of minerals, ores, or other valuable resources within industries like mining, mineral extraction, and ore processing. These tailings encompass finely ground particles, often in the form of a slurry, that remain after the desired minerals or metals have been extracted from the ore. Typically, mine tailings are generated as a slurry, comprising fine mineral particles mixed with water, and may vary in particle size from that of a grain of sand to a few micrometers.

Applications

Main Applications of Tailings in the Construction and Landscaping Industries:

Backfilling: Tailings are used as backfill material in underground mines, effectively filling voids created by ore extraction. This application bolsters the structural integrity of the mine while minimizing surface waste accumulation.

Construction Materials: In certain instances, treated tailings serve as an ingredient in construction materials like concrete and bricks. This innovative use reduces reliance on conventional raw materials, reducing the environmental footprint in construction projects.

Land Reclamation: Tailings are pivotal in land reclamation initiatives, reshaping landscapes and restoring previously mined areas to a more natural state. They are applied to re-contour land and serve as a substrate for establishing vegetation, promoting ecological restoration.

Blasting Agents: In specific scenarios, tailings can be incorporated into blasting agents utilized in mining operations. They assist in the breakdown of rock formations during excavation, enhancing efficiency and safety in the mining process.

Benefits

Resource Recovery: Tailings may still contain valuable minerals depending on the specific mineral extraction process. Advanced technologies can sometimes enable the recovery of additional precious elements from tailings, maximizing resource utilization.

Waste Reduction: The reuse of tailings across various applications contributes to a significant reduction in waste volume that requires storage. This approach could mitigate the environmental impact associated with waste storage facilities.

Land Rehabilitation: Thoughtfully managed tailings are pivotal in land rehabilitation efforts. They aid in the restoration of topography, provide a conducive substrate for vegetation growth, and contribute to the revegetation of previously disturbed areas, fostering ecological restoration.

Reduced Environmental Impact: By identifying appropriate applications for tailings, mining operations can substantially reduce their overall environmental footprint. This proactive approach ensures that waste materials are repurposed constructively, minimizing their environmental impact and advancing sustainable mining practices.

Challenges & Considerations

When Using Tailings in Construction take into consideration the following:

Environmental Impact: Inadequate management of tailings can result in significant environmental challenges, including water pollution and habitat disruption. Responsible treatment and storage of tailings are paramount to prevent adverse environmental consequences.

Safety: Proper design and maintenance of tailings storage facilities are essential to mitigate safety risks, such as dam failures or slope instability, which can have severe repercussions.

Regulations: Various regions have specific regulations governing the management and utilization of tailings. Strict compliance with these regulations is imperative to safeguard against environmental harm and ensure legal adherence.

Characteristics: Tailings’ physical and chemical properties can vary widely, depending on ore type and extraction methods. This variability impacts their suitability for different applications and necessitates careful consideration.

Health Concerns: Depending on the processed mineral, tailings may contain substances posing health risks to both humans and the environment. Rigorous testing and appropriate treatment measures are essential to mitigate these potential hazards.

Products

More like this

Type B Fill

Type B fill is frequently employed as a lightweight backfill material for constructing retaining walls and embankments, particularly in situations involving weaker soils. The term “Type B fill” designates a specialized category...

Type A Fill

Type A fill refers to a specific classification of engineered fill material commonly used in construction projects, providing a stable and compacted base for various structures.Type A material, known for its low permeability, is positioned...

Mud Stone

Mudstone is a type of sedimentary rock that is composed of fine-grained particles, including clay minerals and silt, derived from the settling of clay in calm water bodies. It forms through the accumulation and compaction of these small...

Clean Fill

“Clean fill” is a fundamental term in the construction industry, denoting earth materials, such as soil, rock, sand, gravel, or similar substances, that are devoid of contaminants, debris, or hazardous elements.

Clay Overburden

Clay overburden is the stratum of clay-rich material that frequently overlays valuable subterranean resources or mineral deposits. Typically, it is extracted and temporarily relocated during mining or excavation operations to facilitate...

Clay

Clay is a fine-grained soil material composed of minuscule mineral particles and organic matter. Its notable characteristic is its inherent plasticity and cohesion when in a moist state, while transitioning to a firm and compact form when...

Capping Clay

“Capping clay” refers to a particular variety of clay that develops a natural firm, solid layer or crust on the soil’s surface following periods of rainfall or irrigation as it dries.

Case

studies

Normark

Established in 1977, Normark are a second generation family business specialising in landscape design and construction across Melbourne. "From inner-city Melbourne courtyards to large commercial open spaces, Normark will deliver."

Normark

Established in 1977, Normark are a second generation family business specialising in landscape design and construction across Melbourne. "From inner-city Melbourne courtyards to large commercial open spaces, Normark will deliver."

Normark

Established in 1977, Normark are a second generation family business specialising in landscape design and construction across Melbourne. "From inner-city Melbourne courtyards to large commercial open spaces, Normark will deliver."

Normark

Established in 1977, Normark are a second generation family business specialising in landscape design and construction across Melbourne. "From inner-city Melbourne courtyards to large commercial open spaces, Normark will deliver."

Normark

Established in 1977, Normark are a second generation family business specialising in landscape design and construction across Melbourne. "From inner-city Melbourne courtyards to large commercial open spaces, Normark will deliver."